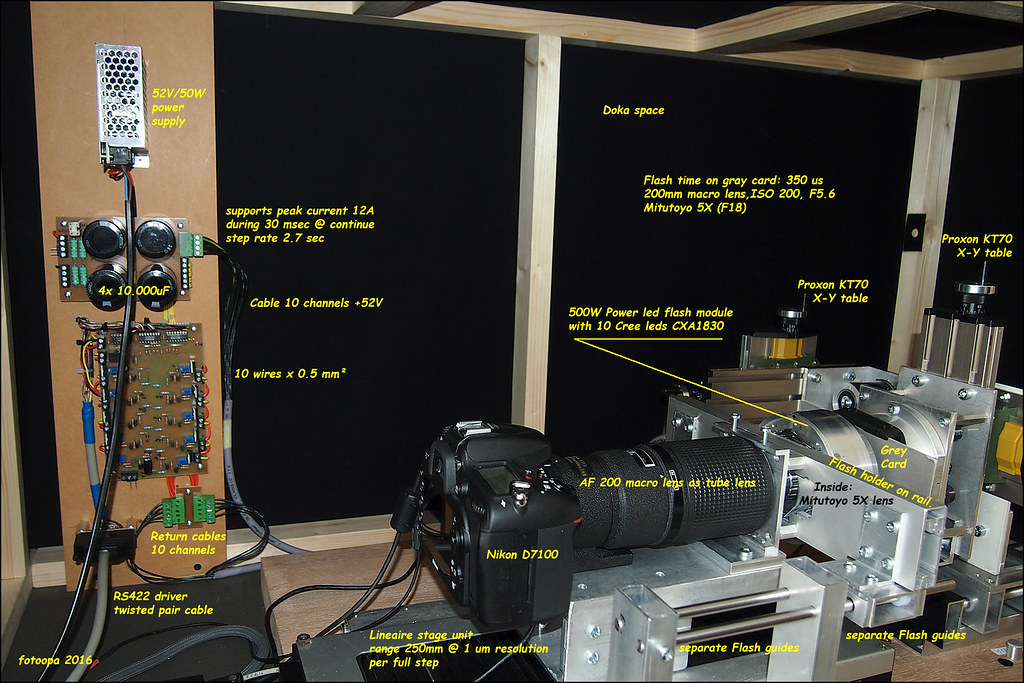

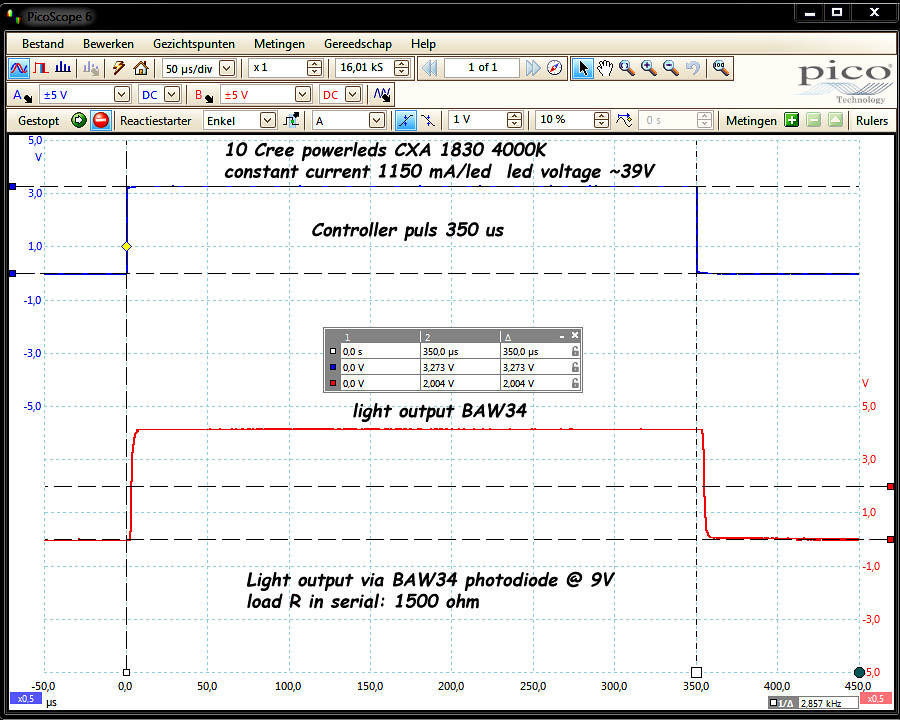

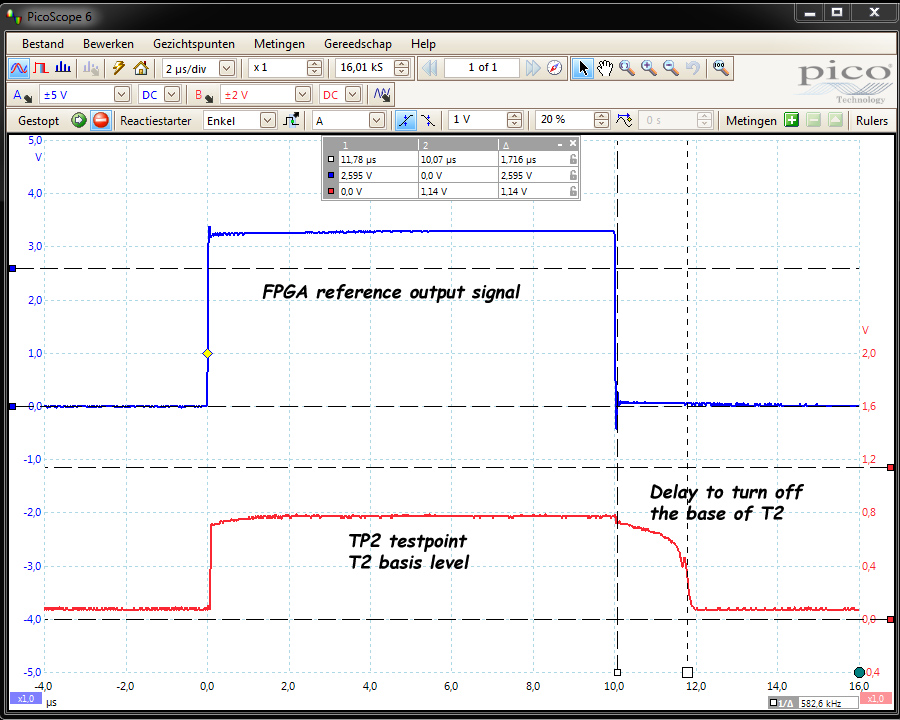

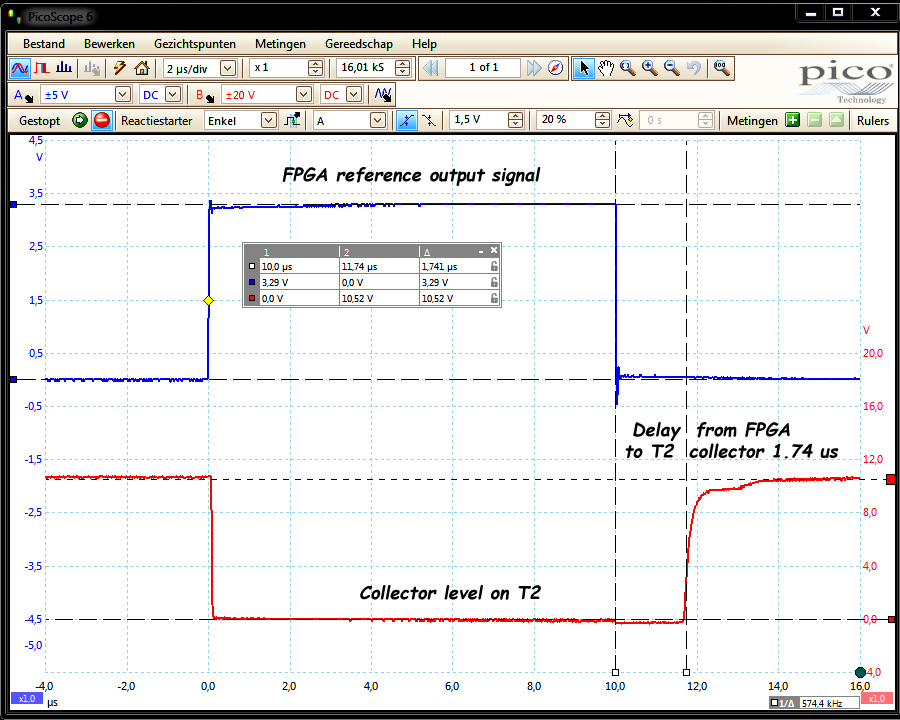

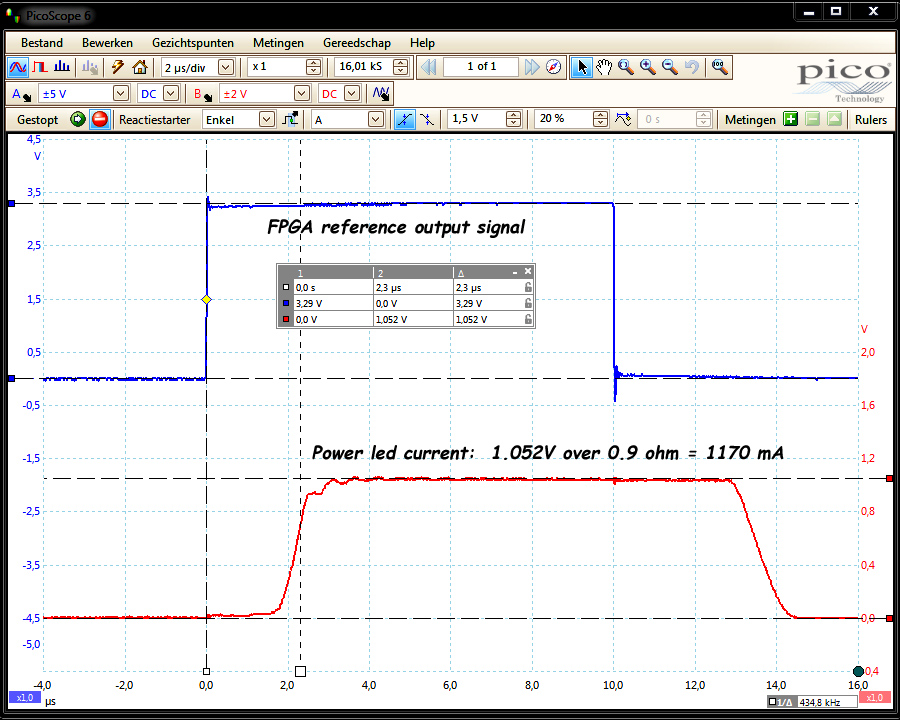

First use and testing of the 10 ch flash LED module.

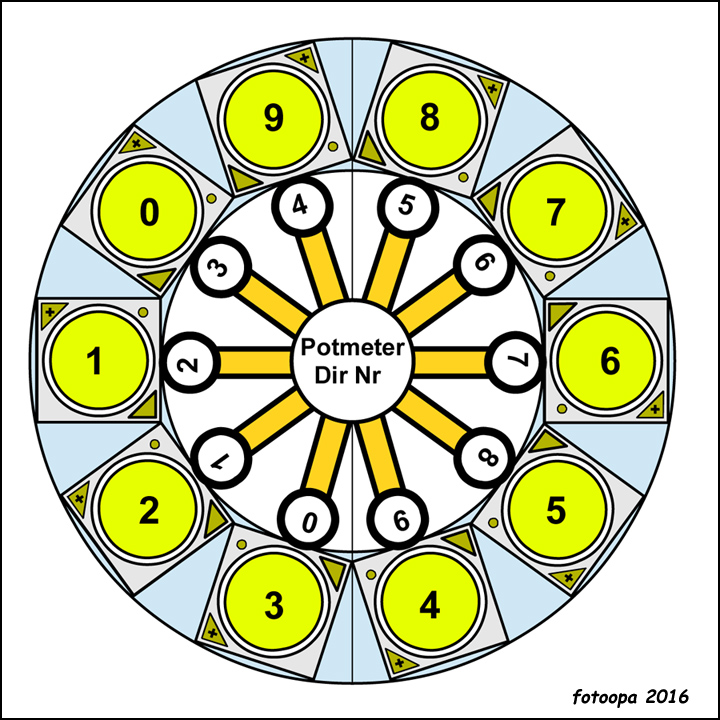

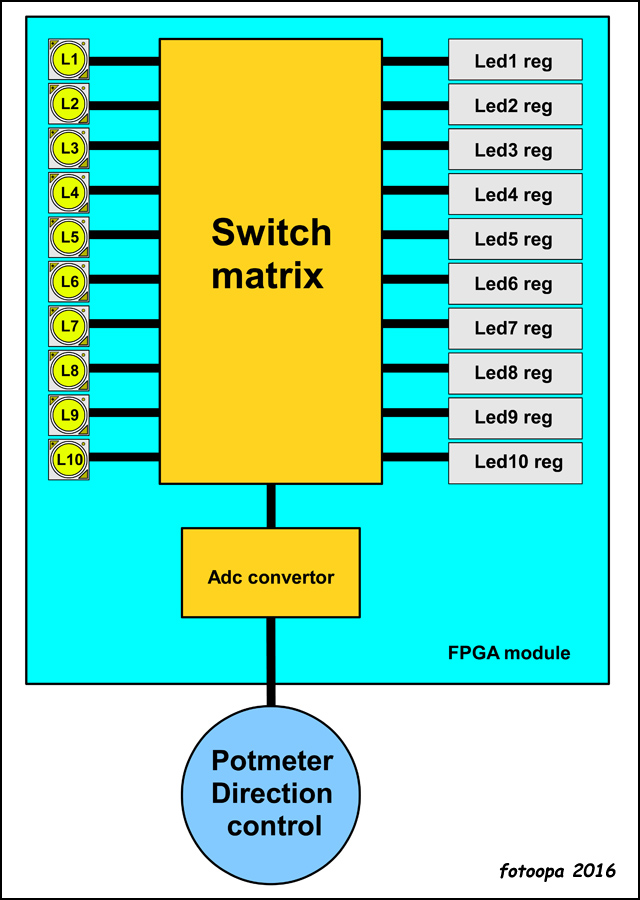

With 10 channels the lighting direction can be changed. For this, the exposure times for each channel should be adjusted and the connection sequence must be able to change.

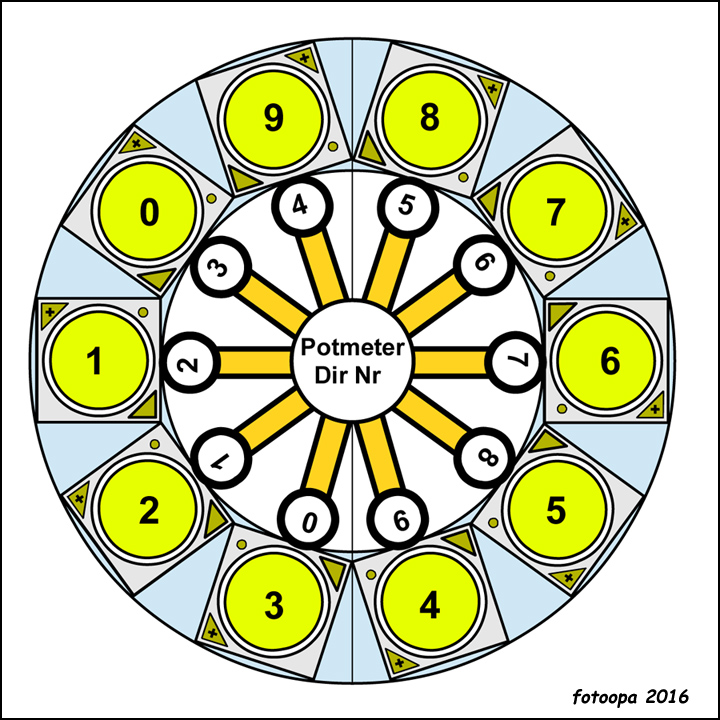

Rotation principle of the 10 ch LEDs:

Rotation principle of the 10 ch LEDs.

Rotation principle of the 10 ch LEDs. by

Frans, on Flickr

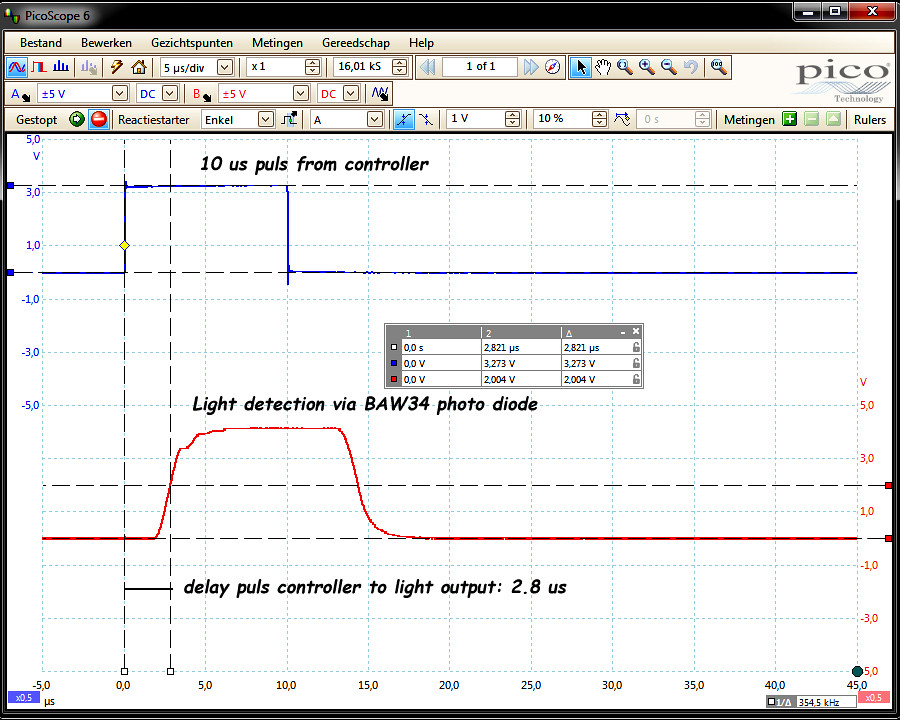

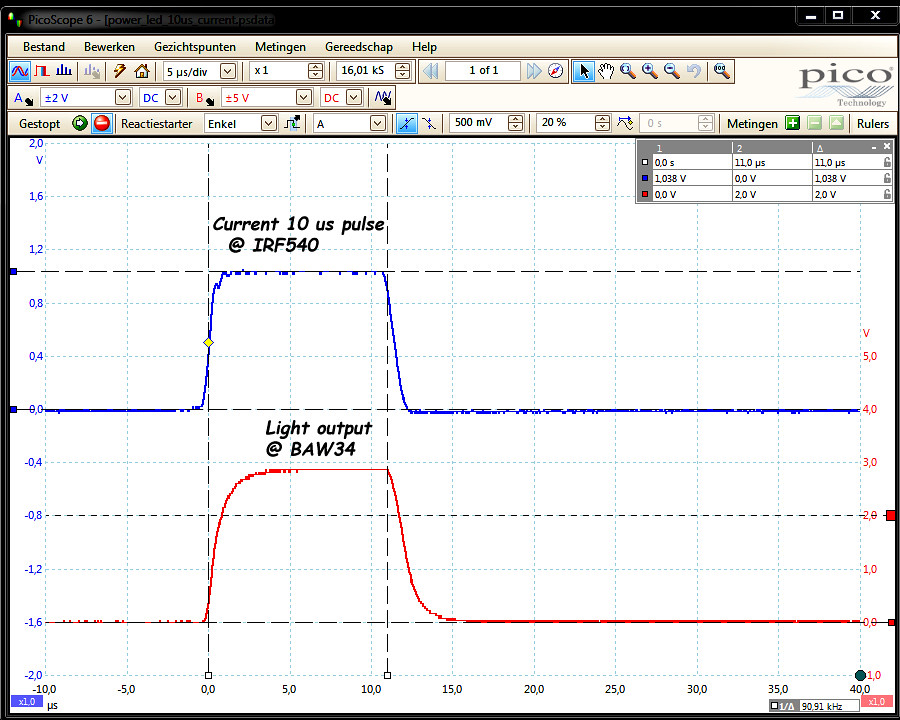

Rotation principle of the 10 ch LEDs. Each LED can be connected to any output register. As a result, the exposure direction can be changed. The individual LED times are sent from a preset table. These values should not change, only the rotation potmeter in order to obtain a different direction.

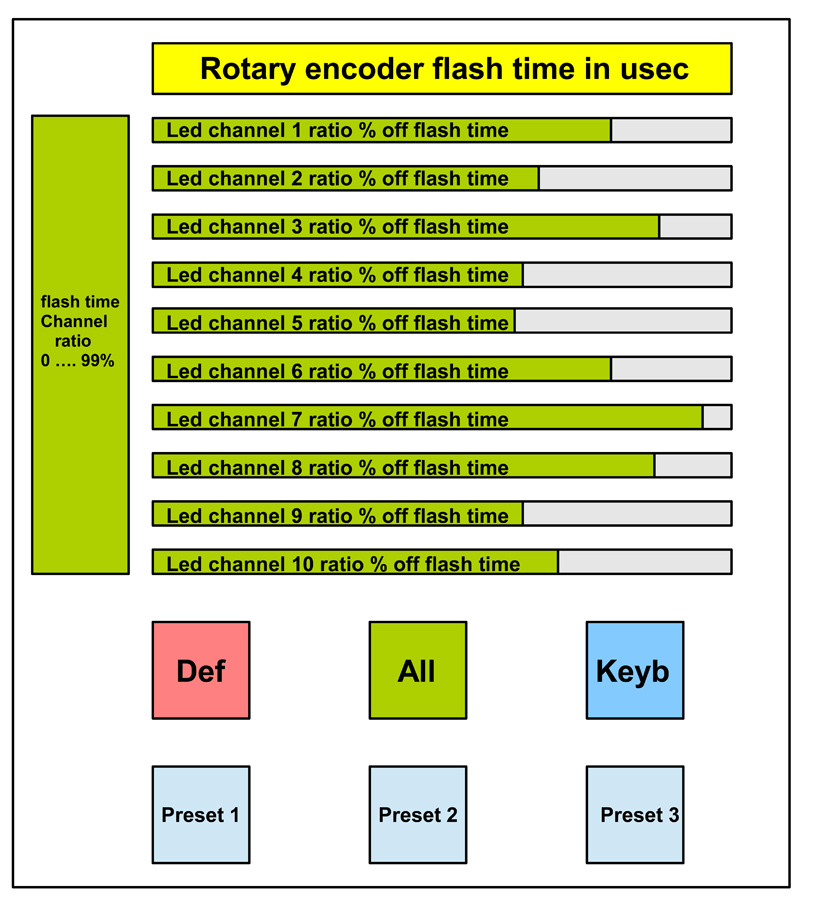

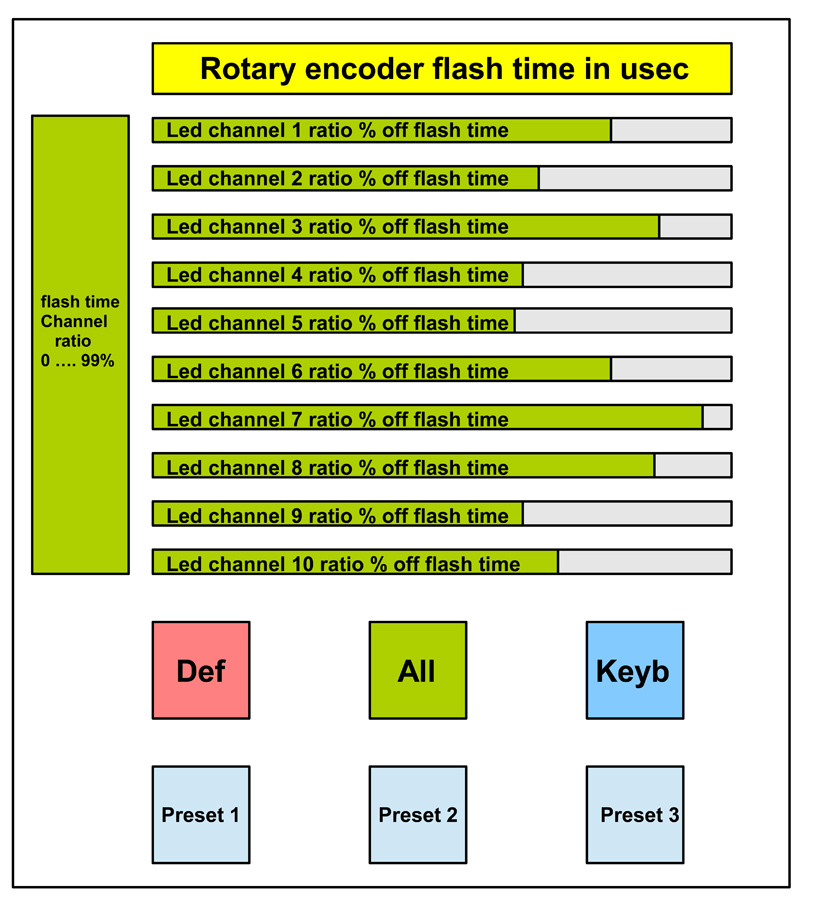

How to driving the 10 ch LED module? The values of the individual channels are expressed in% of the total time. Each channel has a ratio. By now changing the total time you preserve the Original exposure ratio. Slightly more or slightly less exposure can be done via the Time rotary encoder knob. The individual time of each channel is recalculated by the FPGA real time.

A few special push buttons simplify the configuration work.

There is a DEF push button to restore the default values.

An All push button set all channels at the same key entry value.

You can also manually change each channel individually.

These manual values can restore back at any time.

You can also insert a number of presets. These are programmed values for each channel. They are used when you want to give a direction to light. These presets reduce the light output up to 50%, 25% or 12.5%. Thus, the strength of the direction is determined.

Driving the 10 ch LED module.

Driving the 10 ch LED module. by

Frans, on Flickr

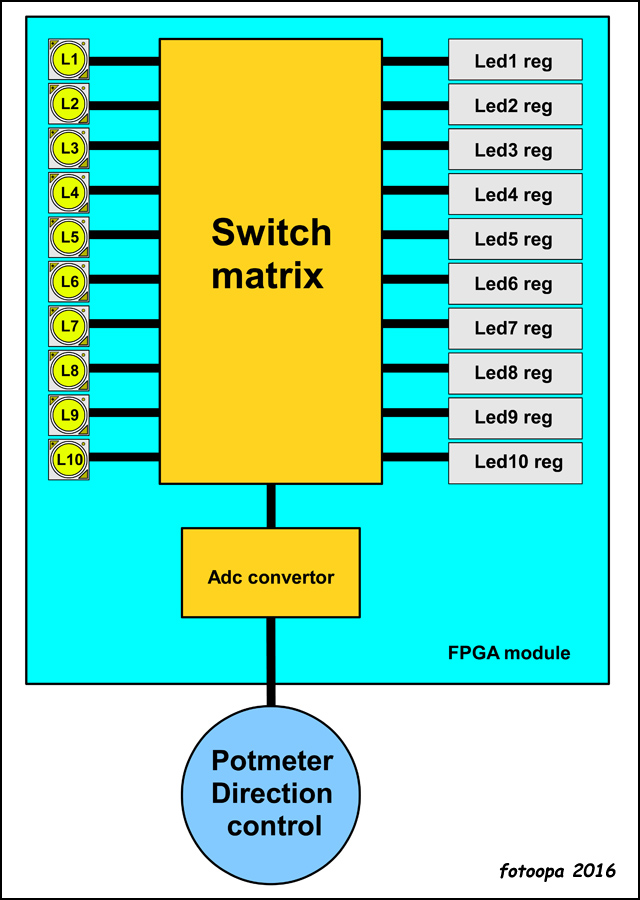

Matrix principle for the 10 ch LEDs. A potentiometer sends an analog value to the AD converter. The FPGA calculated from this 10 directions. The digital information of the direction is used to control a matrix. Thus, each LED can be re-connected to each output register. This results in a rotation.

Matrix principle for the 10 ch LEDs.

Matrix principle for the 10 ch LEDs. by

Frans, on Flickr

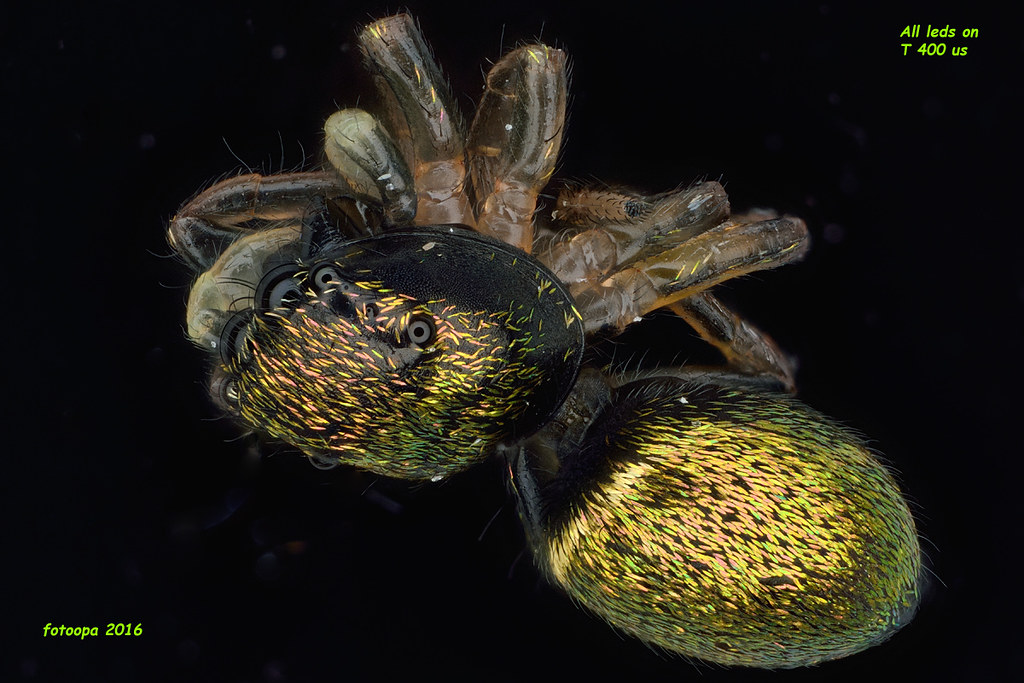

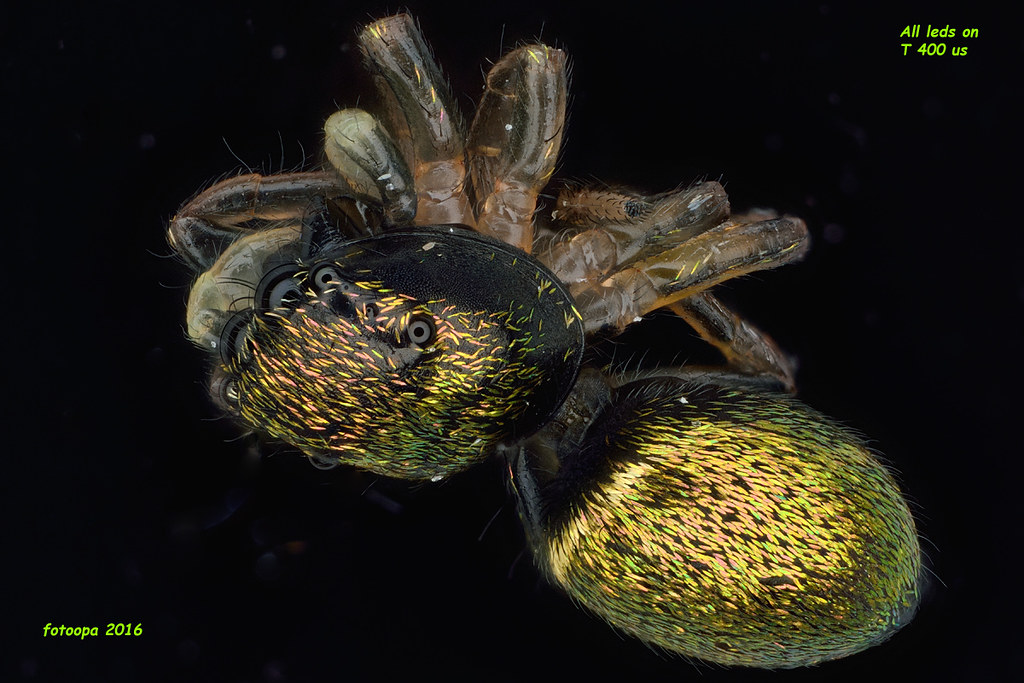

Now time for the field test. Here all leds are at full power. No light direction, this gives a more flat image with less contrast:

Exposure with all leds @ max, no light direction used.

Exposure with all leds @ max, no light direction used. by

Frans, on Flickr

The next recording is done with a preset 25% power distribution over the 10 LEDs. Giving the flash time different values, this creates a direction. Values are presets, just load them via one push button. The DIR potentiometer change the output sequence, thus the light direction. Here the direction is set to D1, not so good choice, the eyes are hardly exposed:

Experiments with changing the exposure direction to D1

Experiments with changing the exposure direction to D1 by

Frans, on Flickr

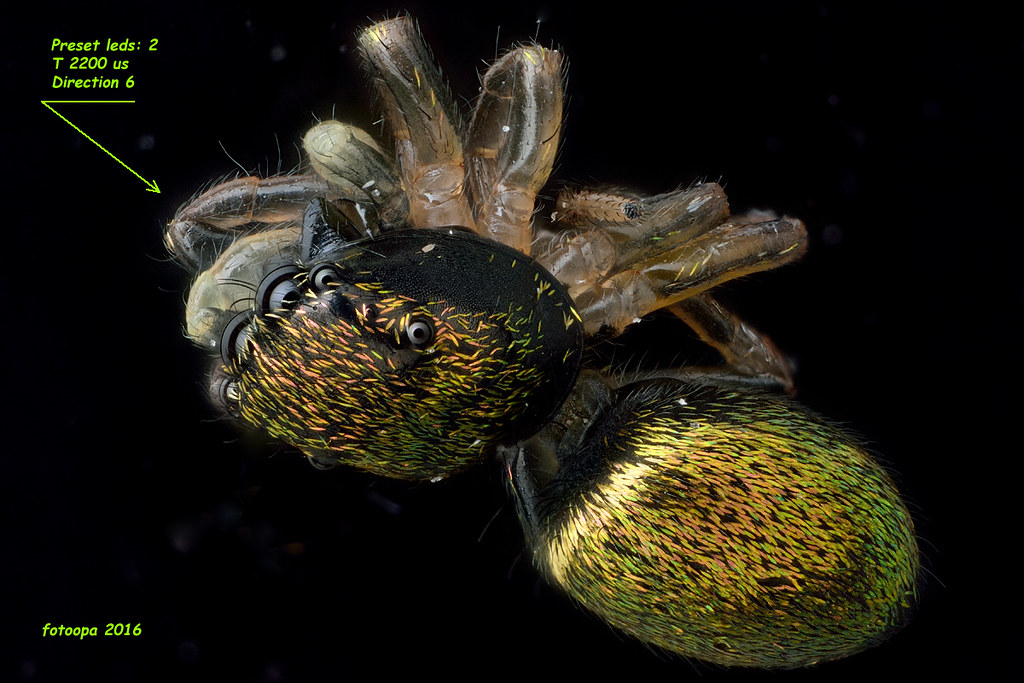

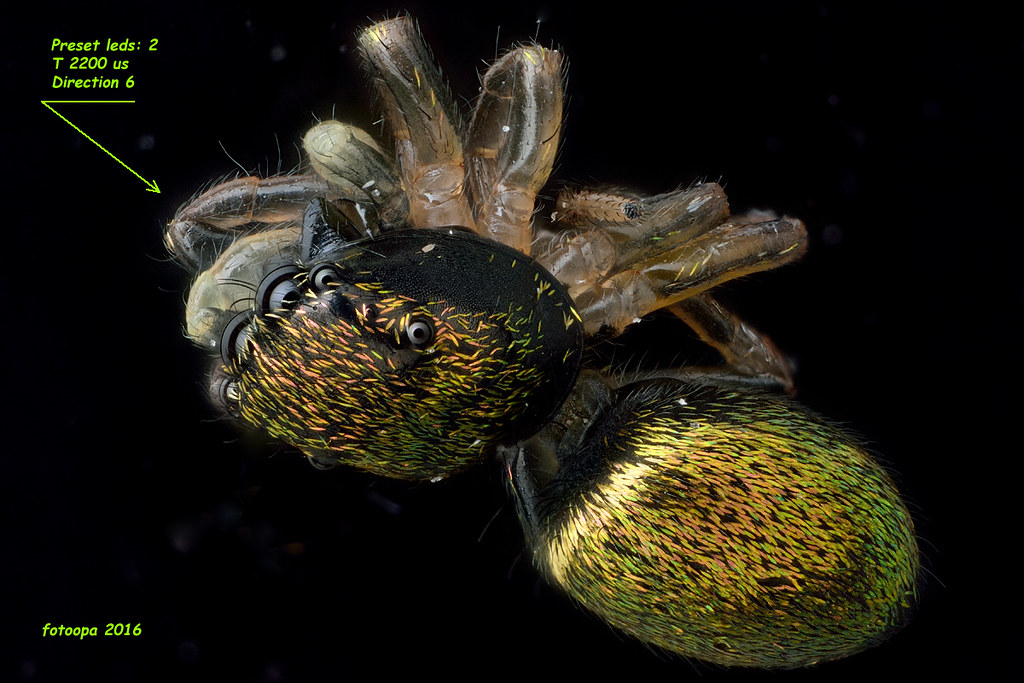

Now let's change the direction of the potentiometer to D6:

Experiments with changing the exposure direction @ D6.

Experiments with changing the exposure direction @ D6. by

Frans, on Flickr

This is definitely better. My higher led power allows to make optimal direction profiles and yet still be used short flash times. This flash led module version gives me new opportunities.

Frans.