Layers of rust

Moderators: rjlittlefield, ChrisR, Chris S., Pau

"Daily use" makes me think of the kitchen or bathroom, and the possibillity that something lurked, rusting unseen due to an undiscovered leak.

I am told that in the north of England, people use their bath for keeping coal. I suppose that if a foot collapsed, the tub would still be good for that noble function.

I am told that in the north of England, people use their bath for keeping coal. I suppose that if a foot collapsed, the tub would still be good for that noble function.

Catastrophic makes me consider part of the chain of the loo cistern...

My extreme-macro.co.uk site, a learning site. Your comments and input there would be gratefully appreciated.

- rjlittlefield

- Site Admin

- Posts: 23608

- Joined: Tue Aug 01, 2006 8:34 am

- Location: Richland, Washington State, USA

- Contact:

Not outside; nothing to do with fire; not a gate hinge; not part of a loo.

But thanks for the many interesting suggestions of things to shoot!

The subject was an internal support member for a Moen single-handle faucet with pull-out sprayer. I neglected to take a picture of it before removing the housing, but it looked roughly like this:

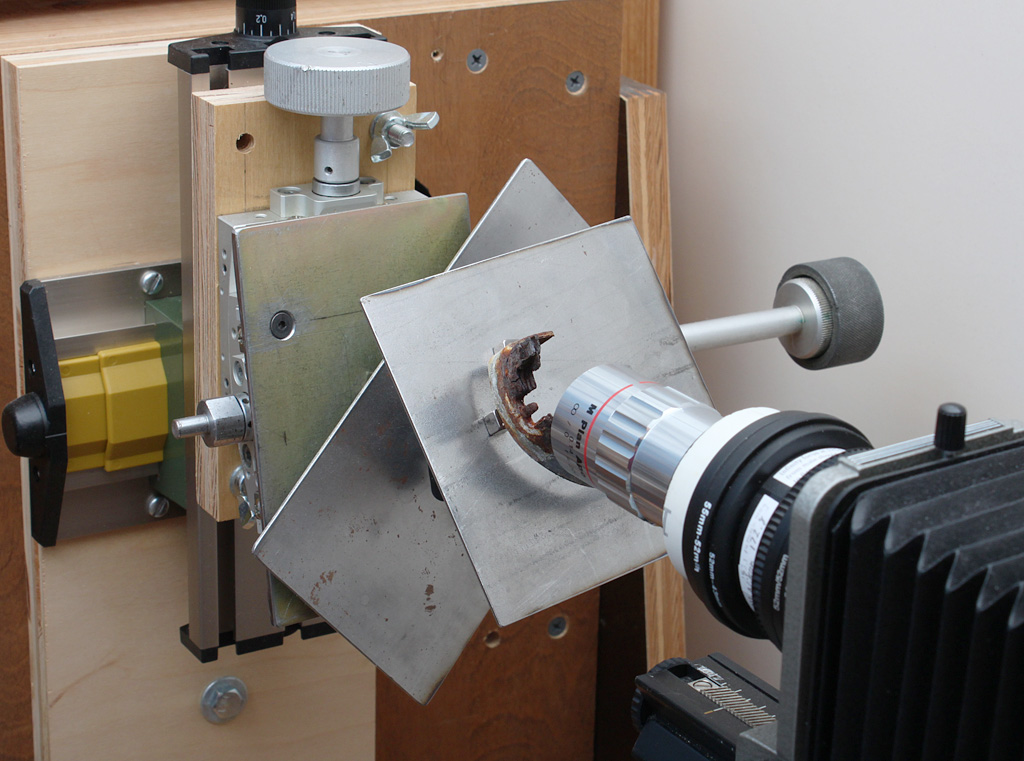

After I removed the nice shiny housing, this is what I saw:

The view from the front was even more inspiring. Notice that you can see completely through the rusted support on the left side! (The spiral wrapped hose has been removed in this picture.)

In the above picture, you can also see that there are three very different kinds of metal in use: brass for the body, copper for the pipes, and steel (now rust!) for mechanical support.

When the exterior housing is in place, it actually can take up most of whatever load is no longer supported by the rust. So until the housing was removed, the thing looked fine, worked fine.

Even with the housing off, if the rusted support had completely collapsed, the brass and copper parts that control the water would still have continued to function normally.

But, um, it seemed advisable to just give up and replace the whole unit.

The nut underneath was so firmly stuck in place that the company-provided installation tool gave way instead. So then I decided to go for a demolition-mode solution: I simply removed the support (by breaking it apart with a screwdriver), then hacksawed through the remaining copper and brass. All in all, a simple job.

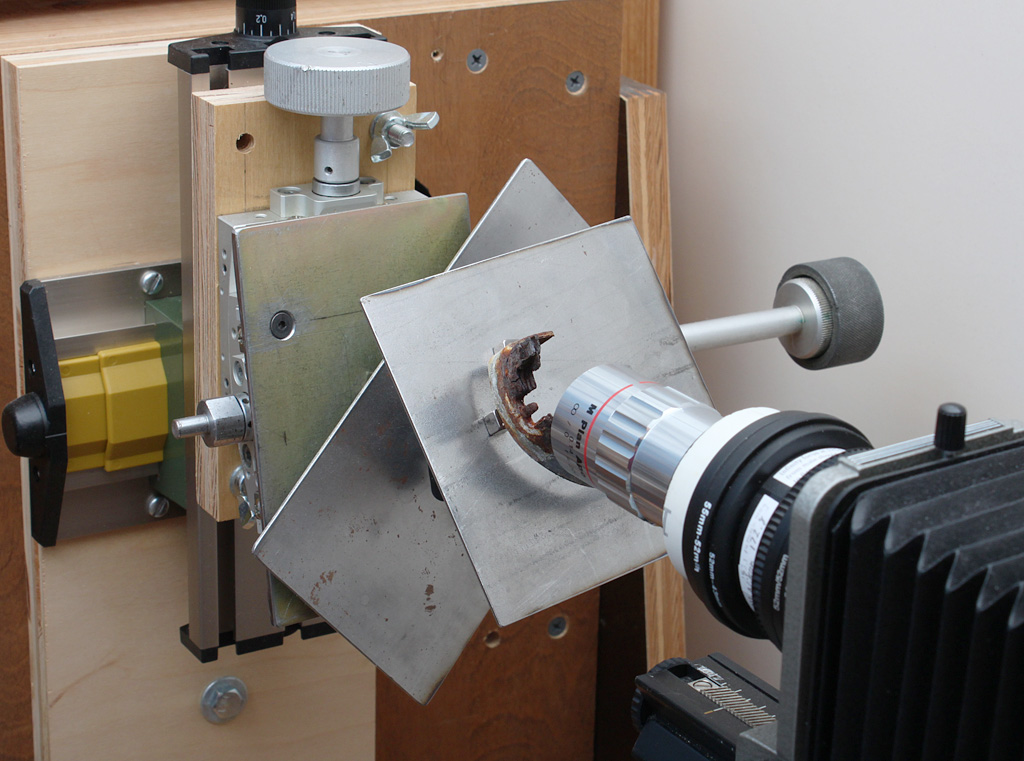

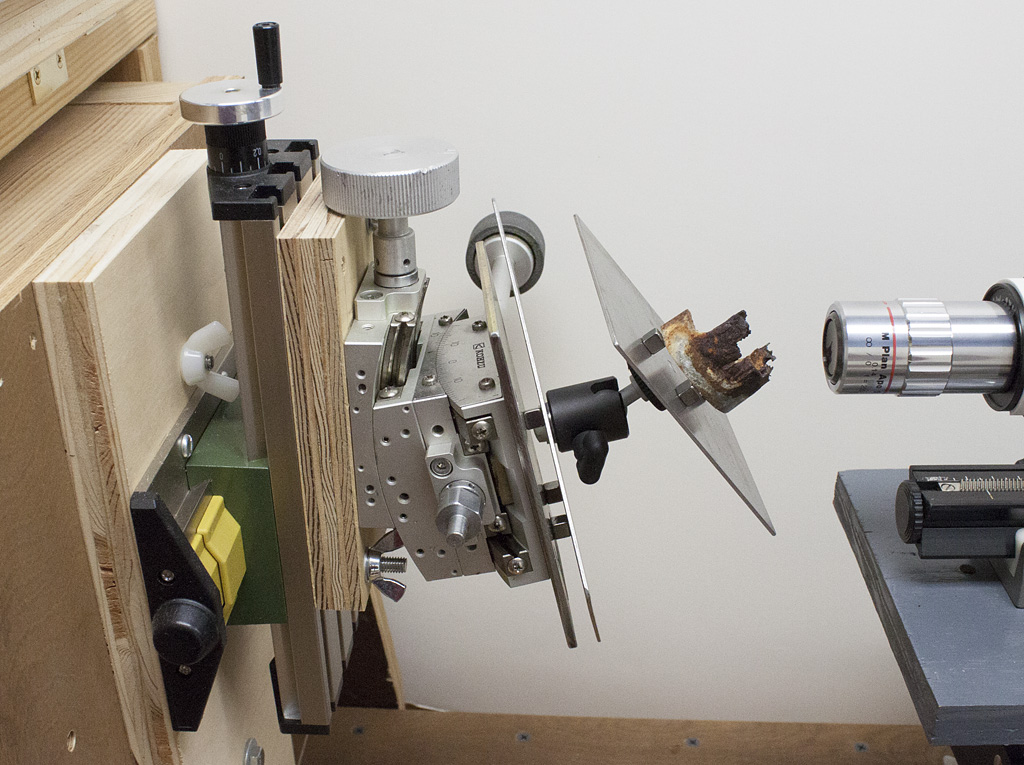

Here are a couple more shots to show what was being imaged in the first set.

The faucet was installed close to 20 years ago. I was the original purchaser, so I could have gotten a free replacement under Moen's lifetime warranty. But I was tired of replacing cartridges in the thing anyway; something in the local water eats the O-rings. So I opted to just pitch it out and put in a completely different kind with ceramic valves. I will be very interested to see how that one fails, if it should manage to do that while I still live in this house.

--Rik

But thanks for the many interesting suggestions of things to shoot!

ChrisR wrote:"Daily use" makes me think of the kitchen or bathroom, and the possibillity that something lurked, rusting unseen due to an undiscovered leak.

Just so!pontop wrote:Part of a water tap?

The subject was an internal support member for a Moen single-handle faucet with pull-out sprayer. I neglected to take a picture of it before removing the housing, but it looked roughly like this:

After I removed the nice shiny housing, this is what I saw:

The view from the front was even more inspiring. Notice that you can see completely through the rusted support on the left side! (The spiral wrapped hose has been removed in this picture.)

In the above picture, you can also see that there are three very different kinds of metal in use: brass for the body, copper for the pipes, and steel (now rust!) for mechanical support.

When the exterior housing is in place, it actually can take up most of whatever load is no longer supported by the rust. So until the housing was removed, the thing looked fine, worked fine.

Even with the housing off, if the rusted support had completely collapsed, the brass and copper parts that control the water would still have continued to function normally.

But, um, it seemed advisable to just give up and replace the whole unit.

The nut underneath was so firmly stuck in place that the company-provided installation tool gave way instead. So then I decided to go for a demolition-mode solution: I simply removed the support (by breaking it apart with a screwdriver), then hacksawed through the remaining copper and brass. All in all, a simple job.

Here are a couple more shots to show what was being imaged in the first set.

The faucet was installed close to 20 years ago. I was the original purchaser, so I could have gotten a free replacement under Moen's lifetime warranty. But I was tired of replacing cartridges in the thing anyway; something in the local water eats the O-rings. So I opted to just pitch it out and put in a completely different kind with ceramic valves. I will be very interested to see how that one fails, if it should manage to do that while I still live in this house.

--Rik

Not the most intelligent mix of materials to clamp together in a potentially wet environment. The electrochemical series...

I don't remember seeing a tap with that combination.

And they can't use an appropriate material for their O rings either?

My portfolio career has taken me through metallurgy and plumbing qualifications, but I think this was covered when I was about 16.

I don't remember seeing a tap with that combination.

And they can't use an appropriate material for their O rings either?

My portfolio career has taken me through metallurgy and plumbing qualifications, but I think this was covered when I was about 16.

- rjlittlefield

- Site Admin

- Posts: 23608

- Joined: Tue Aug 01, 2006 8:34 am

- Location: Richland, Washington State, USA

- Contact:

I'm glad you enjoyed the puzzle. Seems like I never have trouble finding stuff that's interesting to photograph. Finding time, now that's another problem!frankw wrote:Thanks for the "20 questions" game, as well as a lesson both in observing our everyday world,

I don't remember if I've talked about it or not.Also, I was wondering if you would mind giving us a tour of your "specimen holder". If it's already been done, I apologize, I missed it!

Frank

Anyway, here's a quick overview:

The dark brown wood panels on left and bottom are the vertical and horizontal faces of a big L-stand that I made close to a decade ago.

From there, starting on the left, the positioner stack consists of

- piece of 3/4" plywood, serving as a mounting plate for the Proxxon

- Proxxon KT-70 Micro Compound Table, giving vertical and horizontal framing adjustments of 134 mm x 46 mm at 1 mm per turn of the handles

- piece of 3/4" plywood serving as a mounting plate for the goniometers

- matched pair of Kohzu goniometers, rather like eBay 151401387352 (except that oddly the pair pictured on eBay seems to be assembled with the wrong half on top)

- steel plate mounted to face of goniometer with countersunk flathead screws

- three small cube magnets

- steel plate drilled and bolted to Giottos MH 1004 mini ball head

- steel plate drilled and tapped for mounting on the ballhead

- three small cube magnets

- steel subject

I use the configuration shown here a lot, but that's more out of habit and history than for any good technical reason. It has the drawback of limited opportunity for backlighting. For backlighting, a vertical stack of positioners works better. But in that case the "yaw" adjustment, provided here by the goniometer closest to the camera, would be done with a rotary table.

--Rik

As an engineer, I too am surprised at the material selection in Rik's faucet. As an employee of a large corporation, I had suspicions that something "corporate" changed shortly before Rik's unit was manufactured... So I snooped into Moen's history...

http://www.moen.com/about-moen/the-moen-story

20 years ago would be about 1994-1995... Not too long after Al Moen, the company founder, retired...

K

http://www.moen.com/about-moen/the-moen-story

20 years ago would be about 1994-1995... Not too long after Al Moen, the company founder, retired...

K

- rjlittlefield

- Site Admin

- Posts: 23608

- Joined: Tue Aug 01, 2006 8:34 am

- Location: Richland, Washington State, USA

- Contact:

My wife has corrected my abysmal memory; a further search of email archives indicates that it was summer 2004, less than 11 years ago and not "almost 20" as I wrote earlier. Perhaps time appears to fly when you're pretending to have fun. I have notes about having to change cartridges as early as 2009.

About the choice of materials, yeah, I find that difficult to understand also.

If it was actually a design decision, then it had to get signed off by a number of different people who either didn't know what they were doing, or did know what they were doing and had cynically bought into the concept of "planned obsolescence". (The lifetime warranty is only granted to the original purchaser.)

Another possibility is that somebody just screwed up in the material supply chain, so that the support bracket ended up getting made of the wrong stuff. Then surely the people on the manufacturing line would have noticed the change, but it would have been reasonable for them to assume that it had been properly considered and approved by somebody higher up.

--Rik

About the choice of materials, yeah, I find that difficult to understand also.

If it was actually a design decision, then it had to get signed off by a number of different people who either didn't know what they were doing, or did know what they were doing and had cynically bought into the concept of "planned obsolescence". (The lifetime warranty is only granted to the original purchaser.)

Another possibility is that somebody just screwed up in the material supply chain, so that the support bracket ended up getting made of the wrong stuff. Then surely the people on the manufacturing line would have noticed the change, but it would have been reasonable for them to assume that it had been properly considered and approved by somebody higher up.

--Rik