Any last guesses about the dragon's lair, before I spill the beans?

--Rik

Moderators: rjlittlefield, ChrisR, Chris S., Pau

Good question.Rusty wrote:Should the element not have tripped the earth leak protection system when arcing to the outside of the element (ground)?

Maybe wise to check for safety sake ?

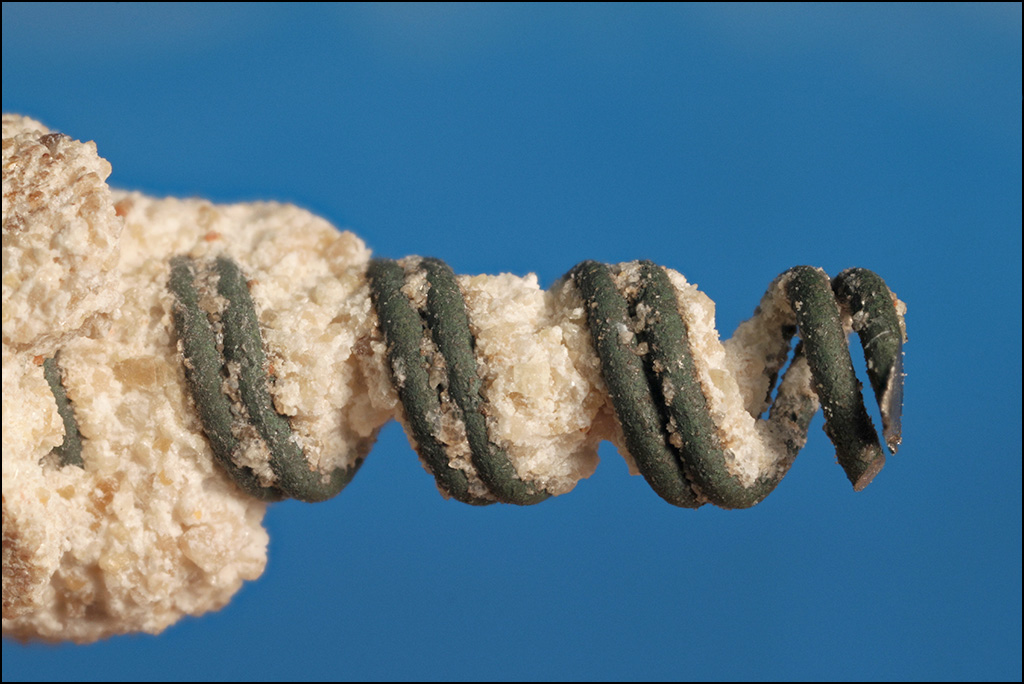

No, these are classic tubular sealed elements ("Calrod" style), and the pot sits directly on the outer shell of the element. There is ceramic insulation, but only sandwiched between the actual heating coil and the outer shell.Planapo wrote:Wasn't there something like the old fashioned solid cast iron plates or a more fancy Ceran glass ceramics plate between the bottom of your pot and that heating spiral?

Ok...that makes sense , we have a different setup where all the individual current breakers works via a main breaker (60 amps) that trips as soon as it senses more than 20milli amps total combinedAll installed safety devices are working fine, but this house does not include ground or arc fault circuit interrupters except for GFCI's on certain plugin outlets (kitchen, bathrooms, garage, yard

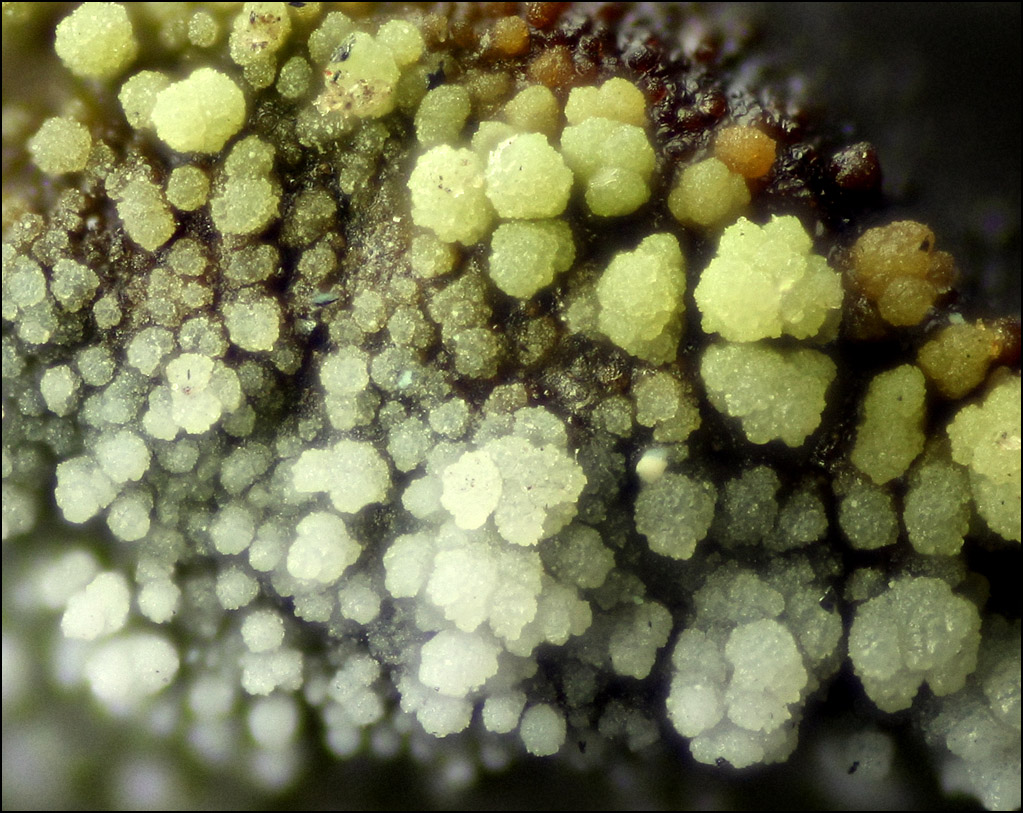

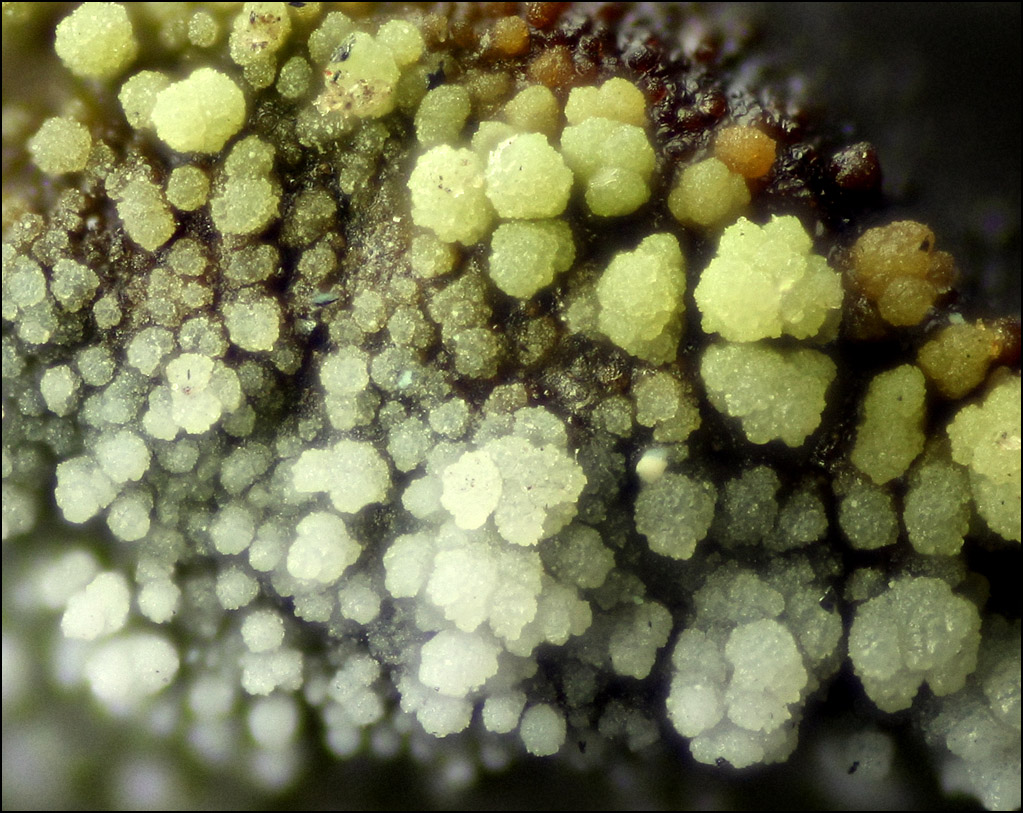

I feel they'd have taken a lot longer than that to form.I suppose that the crystals are some combination of chemicals formed when the arc ripped apart the insulation layer,

OK, but be aware that you're working from incomplete information.ChrisR wrote:Some off-the-cuff musings...

I'm not happy with:I feel they'd have taken a lot longer than that to form.I suppose that the crystals are some combination of chemicals formed when the arc ripped apart the insulation layer,

Sure, but that's in ordinary air. It's pretty clear from the stuff blown around and recrystalized that there was, um, "significant opportunity" for a fairly dense plasma to form. That's the way consumer arc welders work -- high current at low voltage ("typically between 17 to 45 volts") through an arc enabled in large part by flux on the rod. In the case of this burner, it's not even necessary for the arc to be very long at any one instant. As Rusty pointed out, current need only flow from the energized coil to the nearest point on the metal shell, where it can then return through the safety ground. As the end of the energized coil burned back, it would remain only about 2 mm away from the shell, surrounded by a cloud of that recrystalized stuff and goodness knows what else. I suspect that nucleobyte's guess of "Flux coated welding/brazing rod" was pretty much dead on, from a functional standpoint.ARC?? Not much, the UK mains voltage is only enough to produce a spark half a millimetre or so long. (10,000 Volts per inch)

Or maybe something boring like MgO, boiling point 3873 K (well below blue-white), and listed by Wikipedia as being a typical insulating ceramic used in this type of element. The ceramic structure is described elsewhere in Wikipedia as being "a lattice of Mg^(2+) ions and O^(2–) ions held together by ionic bonds." I don't know much chemistry either, but to me this sounds like just the ticket to form a nice plasma at blue-white temperatures, and to quickly recrystalize on relatively cool surfaces.ChrisR wrote:I don't know much analytical chemistry, but I'd expect the crystals would show themselves to be of aqueous-soluble compounds. Maybe something exciting like a spinel?