I was documenting the saga for a friend, got some interesting images, and decided to play with them a bit more for here.

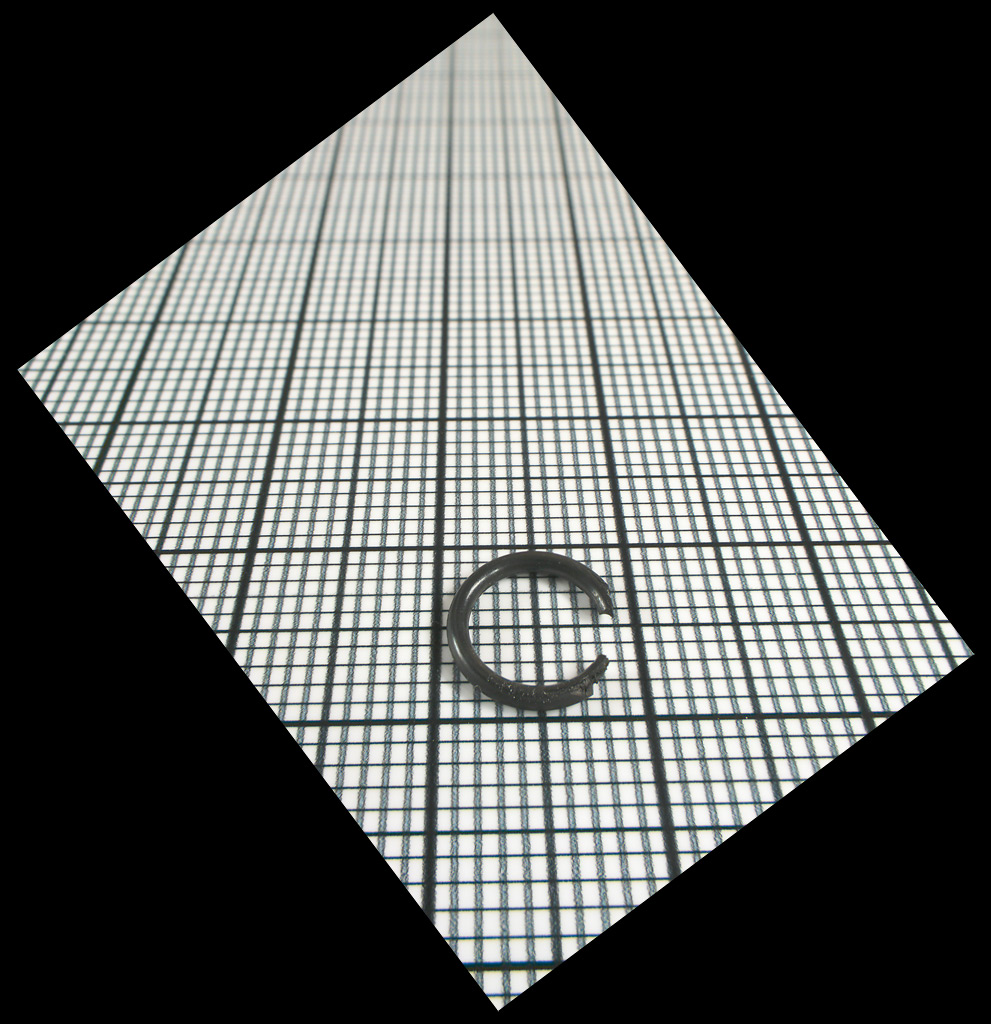

This is the final result:

This was shot with an ancient compact camera, Canon A710 IS, using only its built-in macro capability which includes manual focus. The camera lens does close focus only at its short end, focal length 6mm, which produces a nice wide-angle perspective. ISO 80 at f/4.5, 1 second, 8 frames at smallest focus step. The small grid squares are 1 mm; a replacement O-ring turns out to be 1 mm cross-section by 6 mm inside diameter.

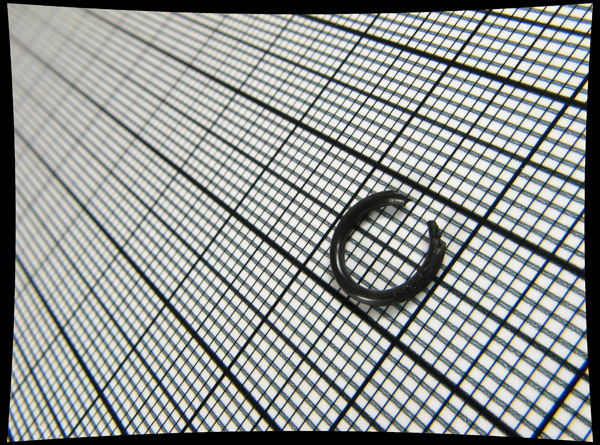

The image has had more processing than I hope is apparent. The perspective of the grid was intriguing, but straight out of camera it has a lot of what appears to be barrel distortion. Unfortunately, the distortion is more complicated than just barrel. Attempting to remove it by lens correction in Photoshop could only turn it from an obvious convex distortion to a less obvious but still annoying "gull-wing" wavy pattern. So I pulled the stacked result into PTGui, set what turned out to be 35 control points to define 5 lines that are supposed to be straight, then asked PTGui's optimizer to find the lens a/b/c distortion parameters needed to make the lines actually straight. It succeeded in getting the geometry good to less than 1 pixel error in the web-sized image. Then I had PTGui render a "panorama" with the lens correction applied, producing an image like this:

I pulled that into Photoshop, applied a couple of passes of lens correction filter to get rid of annoying CA, adjusted curves to bring out some more structure in the broken area of the O-ring, and finally rotated and framed to taste.

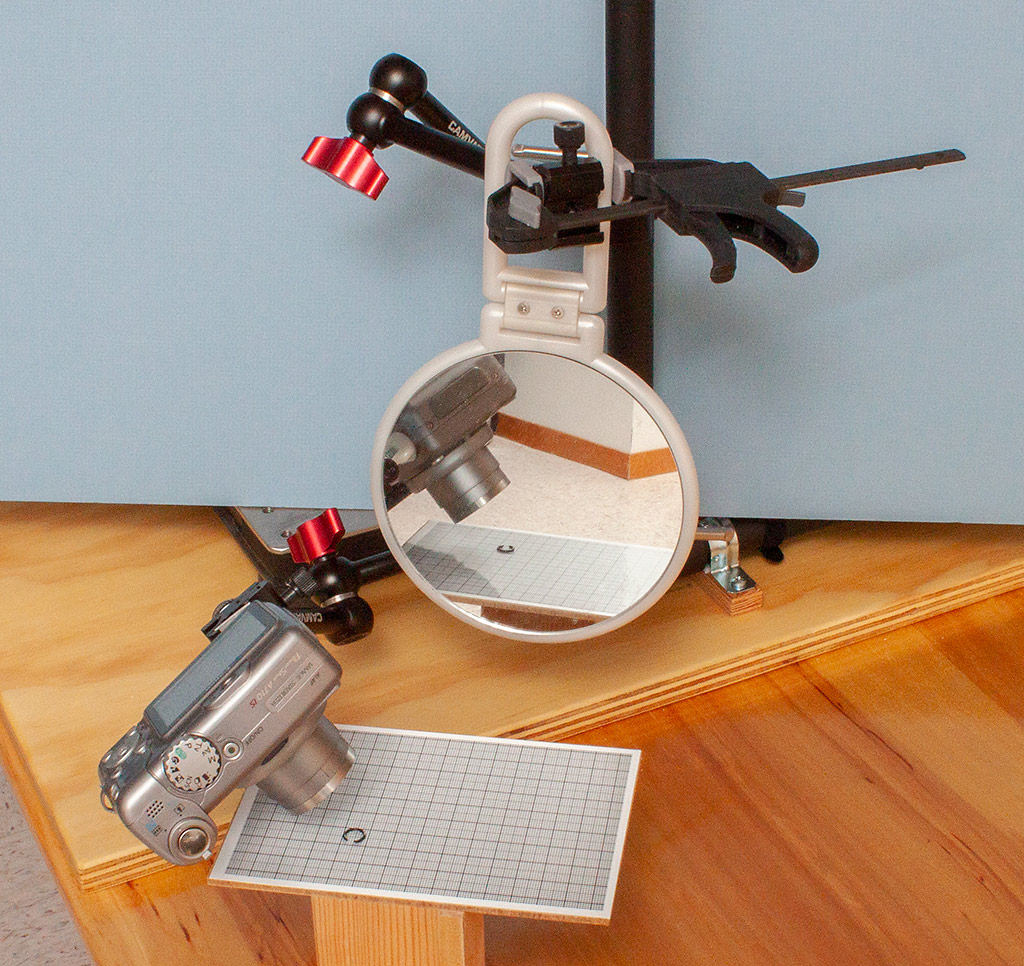

Here's the setup for the shoot. The arms and clamps and black pipe are part of my new lighting cage, described HERE. The mirror is to provide fill light for the shadowed side of the O-ring.

(Screen image simulated)

All told, a lot of messing around for what is mostly an educational exercise. I do kinda like the image though.

--Rik